This is a page where I have collected together all the links for a talk at a small conference over Queens Birthday weekend 2012. The following text is the text I based the talk on. If I had gone through everything it would have probably been a 2 hour talk before even getting to the discussion at the end!

Firstly, if you are new the whole ‘makers’ movement and are a sci-fi buff, check out Makers by Cory Doctorow, available in lots of different electronic formats for free.

The handout is available as odt and pdf.

The slideshow is available as odp and pdf.

This talk is in four parts. The first three describe the past, present, and possible future of 3D printing, with special mention of the Reprap project as my primary knowledge about 3D printing comes from my involvement in this project. After this there will be a time for discussing some of the social implications of 3D printing at the molecular level such that it could be called a ‘Star Trek replicator’. For a quick primer of 3D printing see [7].

I should also mention that most of the dollar amounts are in $US as they have been pulled off various parts of the internet and the de-facto currency has been US dollars.

The Past

3D Printing has a longer history than I am describing here but as the future is more interesting, I’ll stick with mainly post-2000 history.

At this time, there were a handful of big players in the market, along with a number of other less well companies. Machines cost at least $20,000 with the price frequently in the hundreds of thousands of dollar range. Unsurprisingly then, there were relatively few of them sold. Common estimates put the sales figures for the entire industry in a few hundred units sold per year. For this price though, you get high quality prints, normally with precision on the order of microns.

Because of the high price they were only used by specific industries, normally for doing one-off prototypes of a new design. For example, Boeing has made a name for itself within the 3D printing industry as wanting to always have the biggest and best 3D printer to prototype their jet engines so when they bought a new 3D printer, the vendor they bought it from would get a lot of marketing mileage out of it.

The printers were not what you would call ‘portable’ with most standing man-high they could weigh a significant fraction of a tonne. Most would generally print in one type of material so a machine that could do multiple types carried a hefty premium.

This is because the printers take small pieces of a material and attach it, normally by chemically bonding it, to other pieces. There are 3 main types of printers: those that use plastics, those that use ceramics, and those that use metals.

In most cases they use the material in powder format and use lasers or some other focussed heat source to melt small pieces of powder together. There were also some that used a liquid and induced a phase change to turn it into a solid. Normally this would be UV light focussed on a photo-polymer liquid.

The Scott Summit talk [1] talks about some of these different types of printers from 10 minutes 40 until the 12 minute mark.

The Reprap project was started against this background with a press release on the 2nd Feb 2004. Dr Adrian Bowyer had an idea, and created a wiki, blog, and email list to facilitate others who wanted to help him with it.

The idea is very simple. If you can design a 3D printer that can print its own parts then it doesn’t really matter how expensive the first one is as very quickly you can get down to the cost of just the raw materials. You also don’t need a shop to sell them from as you can get one from a friend who already has one. If people print off copies for friends then you get exponential dissemination of the printers as well.

There isn’t much point in making the design secret and if you make it open then you also give the ability to test changes to the design to the entire population of people who have a printer already. If they also publicise not just their successes but also their failures, you have something more akin to evolution of the design rather than simply a focussed process based on iterations of design and testing. This is explained well in the general introduction video created in 2009 [11]. There are also a number of hour long talks that have been given on the Reprap project, with [12] and [13] being two that I consider to be especially good.

As mentioned in the video, the first Reprap version, the Darwin was initially assembled with parts printed on a commercial Stratsys Dimension with the first replication happening on 29 May 2008. It has been estimated that the printed parts for the initial Darwin were $3,000 but the parts used in the second used approximately $30 worth of plastic.

Since this first replication the number of working repraps have increased enormously to the point where it was estimated that at the end of 2010 there were 4,000 of them.

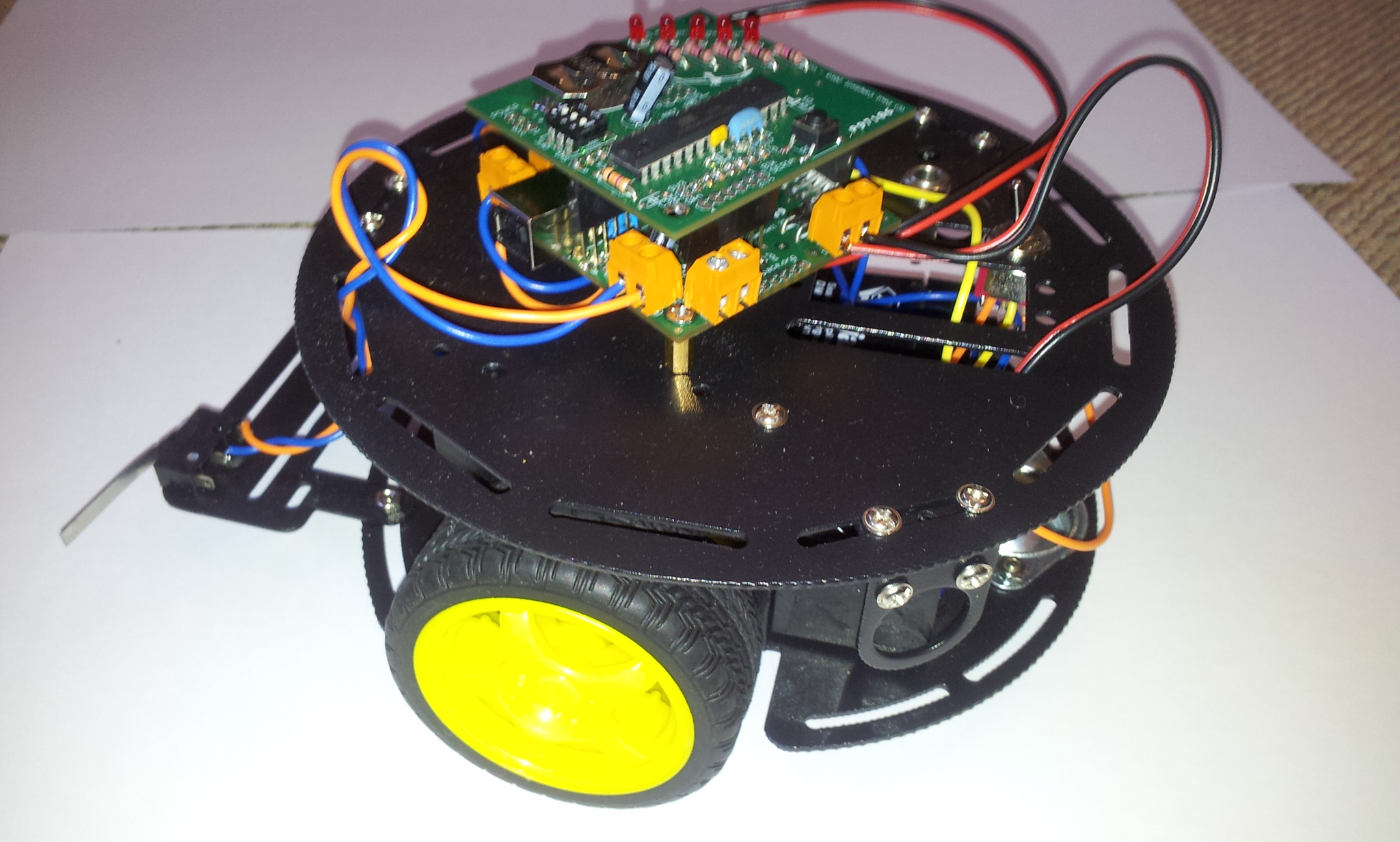

I have been involved in the project long enough that I some basis for making estimates on the cost of the various models of Reprap machine. In 2008 when the Darwin model came out I would estimate that it would take 40-80 hours to print its own parts. These parts made up about 60% of the parts used in the machine with the other 40%, called vitamins, being able to be bought about $NZ800.

A year later in 2009 when the Mendel model was released this time went down to 30-50 hours due to radical redesign of the machine. There were significantly fewer parts and although it would only be able to print 50% of its own parts the lesser part count meant that the vitamins might only cost $NZ700.

In 2010, Josef Prusa redesigned the Mendel to be quicker to print, with fewer parts again. This has become the standard model newbies are suggested to build by the community and it can print 60% of its own parts in 20 hours, with the vitamins costing $600.

And,in late breaking news, this week a new kickstarter project has started up: the Vision 3D printer which is a modified Prusa Mendel. According to the kickstarter page http://www.kickstarter.com/projects/vision3dprinter/the-vision-not-just-a-3d-printer-a-dream this printer can be built in 1/3 of the time (from the experience of Dunedin Makerspace people putting together their printers I think this probably means 3 hours) with 150+ fewer parts. Obviously this part count is counting little nuts and bolts to sound impressive but its those same things that are quite annoying. 70 of these parts, including 8 printed parts, are replaced with 2 acrylic panels. There are a few pictures on the kickstarter project page about it.

One of the most interesting things about the Reprap project is that, according to a survey done by Erik dr Bruijn for his Masters thesis [15], the number of people involved in the Reprap project has been doubling every six months, at least up until the end of 2010. Actually, he was even more precise and estimated it as doubling every 6.03 months or 6 months and 1 day!

He estimated the number of people involved in the Reprap project in total as 4-5 times the number of people who took the time to complete the survey based in part on the number of people (or unique email addresses probably) registered for the various mailing lists etc. that he sent the link to the survey to. This could also underpin some/all of the other doubling periods of other measurable things in the hobbyist 3D printer space.

The Present

Coming more to the present the number of big commercial companies are decreasing as they merge with each other. Some of hobbyist 3D printer companies have also been snapped up by the big boys.

The cost of the printers offered by these companies is also coming down. A friend tells the story of how a $100,000 printer bought new 5 years ago can now be bought on e-bay for $20,000. The equivalent printer new has come down to $80,000. The floor for these printers has lowered to $5,000 to meet the ceiling for the hobbyist 3D printer market which has just expanded so rapidly that it has been called a “Cambrian explosion”. In 2011 there were at least 30 small start-ups selling hobbyist 3D printers for $500-$5,000.

The size of the printers has also come down with the worlds smallest 3D printer able to fit in the palm of your hand. It is a liquid based model that can print objects in a build envelope of only 20 x 30 x 50mm with layers of 50 microns. At a speed of extrusion of 1cm of height per hour, regardless of base area, it will have a maximum print time of 5 hours. There is a TEDx talk about it [10] with the website being [14].

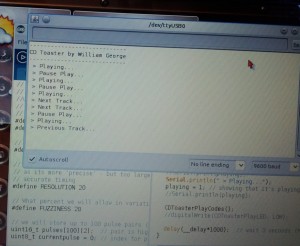

I have a Makerbot Cupcake that was purchased in 2010 from a small company that has established itself as one of the leading companies in the hobbyist printer arena. They started in 2009 and it was estimated that the number of printers they sold in their first 18 months of business was approximately the same number as the yearly unit sales of the rest of the commercial 3D printing industry combined!

The last few years have seen a rise in the differentiation of the hobbyist designs. Compared to my Makerbot Cupcake there are printers now on sale that can extrude 10 times faster, or at 5 times the level of detail. In fact, the hobbyist market in general are starting to measure tolerances in microns rather than millimetres.

There is also at least one design, currently unreleased but mentioned in discussions with Vik Olliver from Auckland, that does not have any nuts at all. Apparently everything just clips together and you can just give it a light tap with a mallet at the right places to make sure everything is seated properly.

So, what can you do if you have a 3D printer? Well, if you have computer aided design (CAD) skills then you can design your own parts to print but if you don’t you will need to use someone else’s design. The websitehttp://thingiverse.com was created by Makerbot for the community so that designs can be shared and, as everything is under open licences, you can change someone else’s design and even do ‘mash-ups’ of designs.

I have been keeping track of the number of things on thingiverse for a while and the number of things available has been doubling approximately every 6 months. At the end of May 2012 there were over 24,000 items available. Edit: I just looked at the highest thing id number but as Vik Olliver pointed out ‘A good guide, but doesn’t take into account that more than one object may be hosted on one page, or handle deleted objects. Just go to the “Newest things” page and look at the number at the top.’ This is still nearly 19,000 with another being added every hour.

In the biological arena, researchers have been using ink-jet technology to ‘print’ cells and scaffolding to create simple organs for a number of years. Simple organs in this context are those with only one type of cell such as a blood vessels or a bladder. They are now starting to have success with more complex organs, such as the kidney which consists of many different cell types. This is discussed in the TED talk [8], especially from 7 minutes 25 seconds to 12 minutes which shows some different methods of doing this and a printed kidney. Although, as the text overlay in the video mentions, this won’t be ready for human implantation for a number of years.

Another milestone is that, in the last couple of years, 3D printing has started to be covered by the main-stream media as not just something that is here now if you’re rich, although Jay Leno does a good job of explaining what he can do with his in [5], but also will be here tomorrow for everyone. The TVNZ ONE News article [3] is a good example of this.

And now, on into the more speculative part, the future …

The Future

What are we wanting: the Star Trek replicator! For those that are unfamiliar with it, it was made famous in the Star Trek: The Next Generation series when Captain Jean-Luc Picard ordered “Tea, Earl Grey, Hot” from it, seemingly every episode or two. In fact, there is a small montage of this up on Youtube [6].

Neil Gershenfield in 2006 said “Twenty years from now, we’ll have Star Trek replicators that can make anything”. He said this the context of being the head of an MIT project, the Fab Lab, that put everything you would need to make just about anything, from the micron scale to the metre scale, in a shipping container sized area and transported them to lots of weird and wonderful places to see what people could do with them. The cost of this set-up has been coming down every year so that it is now less than $100,000. Most of these tools were subtractive, i.e. they took a big something and cut bits away from it, rather than the 3D printing additive technique. Should we believe him? If we do then we’re now only 14 years away from the Star Trek replicator.

The problem is that he also said this in 2010! I think his original time-line was pretty accurate but I’d also like to fudge my numbers a bit and say that we can get to something like the Star Trek replicator in 10-20 years from now, 2012. If you want me to pin it down further though, I’d say it was closer to 10 years than 20, so in the range of 10-15 years.

When I am talking about ‘something like the Star Trek replicator’ I am talking about a Desktop Nanofactory as shown in the video [4]. [2] is also an entertaining little animation of the past, present, and future of manufacturing.

One benchmark to see if we’re on track is to see if the Interim Gada Prize [16], worth $20,000 is awarded for work done until the end of 2012. In part, to claim this prize a team will have to have a printer with:

– Ability to print at least three different materials, including one that is usefully electrically conductive.

– Ability to print electronic circuit boards.

– Total materials and parts cost under $200 and that 90% of the volume of the printer parts be printed.

– Build volume of the printer above 300x300x100mm in order to ensure that items of daily utility can be printed.

– The capacity to print a full set of parts for a complete replica of itself within 10 days unattended save for clearing no more than one printer head jam.

– Ability to print autonomously without a PC attached.

– Uses no more than 60 watts of electrical power.

I think these goals are achievable but I don’t know of a single machine that currently can do all these. I am hopeful that the prize money will motivate enough people that most, if not all, of these goals can be met by the end of the year. If this happens there is a Grand Prize to be awarded at the end of 2015 worth $80,000 but this has not yet been funded.

Speaking in generalities, to get to this desktop nano-factory from the current hobbyist printers we will need to get more people passionate about what they can do with them. For this to happen there needs to be more features that are obviously useful to everyone such as: more personalisation of objects, more designs of objects available, more materials able to be printed at better resolution, faster.

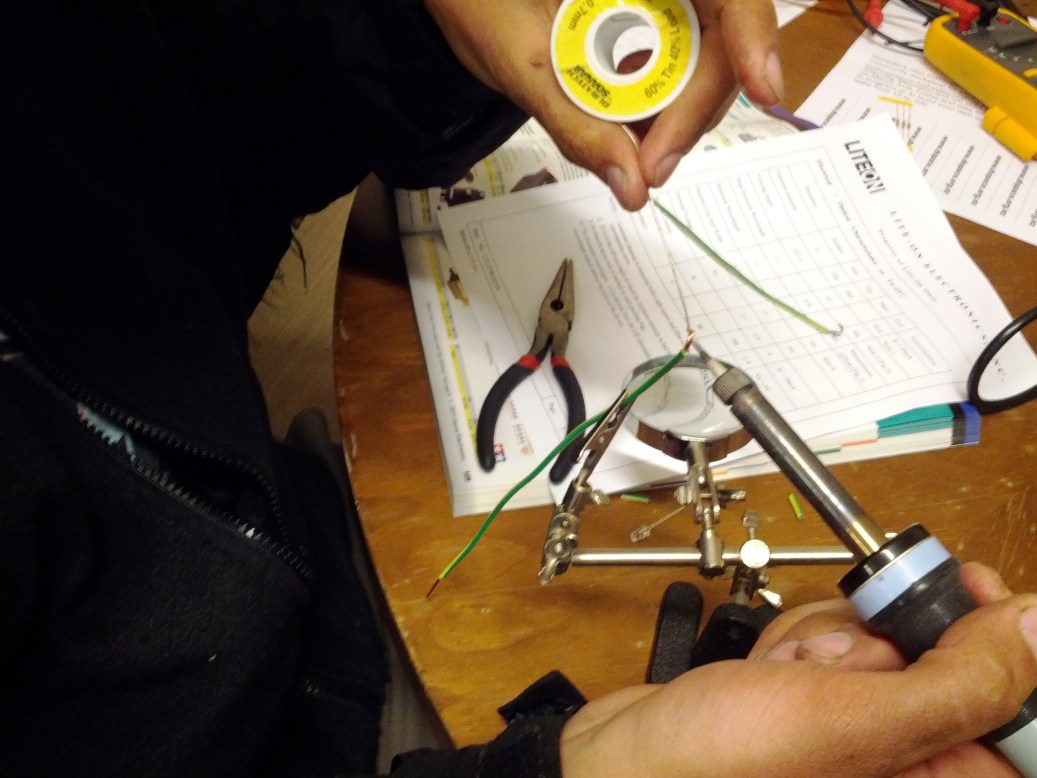

The Reprap community is currently working on all these in the disjointed fashion of open source projects everywhere where each person is ‘scratching their own itch’. Of interest to me is the research that has been going on over the last couple of years in printing electrically conductive materials, which could lead to the printing of the circuit boards for the electronics for all new machines in the near future.

There are also competitive people in the community who are testing the limits of their printers and designing ways around them to print faster or with better resolution than others have achieved, even if only for for bragging rights 🙂

And now we come to the social implications of all this where I would like some audience participation as I don’t really have any answers, just a number of questions to start things off.

Social Implications/Discussion

First, a little refresher on exponential functions. I would estimate that it currently takes 40 hours to print out the parts for a Reprap machine and put it together, even if you make every rookie mistake. If we spread that over 4×10 hour weekends, then we have a month, if we spread it over one weekend a month we have 4 months to have a working 3D printer from scratch. If you make one for yourself and use it to print off parts for two friends, and they do the same, how long does it take to get one to everyone on the planet?

After 30 doublings, you have over 1 billion printers, say 1 per family. After 3 more doublings you have one to everyone in the world. If each doubling takes one months thats less than 3 years. Even if each doubling is 4 months it is still only ten years until you have one per family, and less than a year later you have one to everyone.

It is unlikely that the printer at the end will bear much resemblance to the initial printer if it takes 10 years but at what stage would the first printer have to be for the eleventh year to be printing desktop nano-machines? I am going to say, with no evidence, just a feeling that may be wrong, that the initial quality printer could be no better than the average hobbyist printer available today. At the very outside I would say you could start the clock on this transformative decade in 5 years time!

So, what happens when the social changes of the Industrial Revolution are compressed into a decade? I am taking it as a given that there will be massive social changes from the common availability of a desktop nano-factory type of 3D printer and would be interested in hearing any arguments to the contrary as I haven’t really heard any strong ones.

The Centre for Responsible Nano-Technology (CRN) held a workshop in 2007 where they discussed how nano-tech could come into being and one of their eight scenarios was the grassroots use and enhancements of open source 3D printers such as Repraps, see [17]. This is just a document to get the discussion going and I am not tying any meaning to the actual dates in it. What I would like to do is rather discuss what sorts of things we, as a society, will be grappling with over the next decade or two.

Some questions that came up at the octacon presentation:

Is this actually going to happen? Is the exponential dissemination going to keep going? I take this to mean, are the overwhelming majority of people going to want a 3D printer/desktop-nanofactory if they could have one? This just needs some simple R&D by the community I suspect. If everyone who currently has a Reprap shows it off at every opportunity and people say “Thats cool but I wouldn’t use it because…” then the community at large can collectively figure out what changes need to be done to make it more useful and desirable. I suspect that this will happen anyway but I want to put it out there as something that should be done intentionally.

Another good question was about the power consumption of the world population of 3D printers/desktop-nanofactories vs. the power consumption of today’s traditional manufacturing techniques. Because efficiencies of scale probably also apply to power consumption it was thought that a lot of individual 3D printers would use more power collectively to produce the same amount of goods. One thing I didn’t think about until afterwards was that this might be balanced by the more efficient use of materials in the additive manufacturing process of the 3D printer rather than the current model of subtractive manufacturing and a long chain of value-add companies along the way from raw materials to finished product.

The following are just some initial Discussion Questions that were used to get the thought processes going (the discussion quickly went away from them of course):

What jobs are destroyed, what jobs are changed beyond recognition, what ones are left alone, and what new ones are created by this technology?

What if you could print 3 meals in a 24 hour period from some dirt, atmosphere, and solar power?

What happens to farming,agriculture, and the whole food industry?

Is 3d printing using the atmosphere as feedstock a viable ‘carbon sequestering’ technique to combat climate change?

We already have enough food for everyone, the problem is distribution. Does this solve it or just make the politics worse?

What has value if everything can be duplicated at the molecular level?

Are expensive pieces of art valuable because they are rare or because they are beautiful?

Will individual craftsmen become millionaires because they make one-of-a-kind things?

Current economic theory is built upon the fundamental assumption of scarcity, what happens to economic relationships in a post-scarcity world?

If we can personalise everything, will we? Clothes are desirable to be fit to our body rather than picking from an arbitrary sizing system but what about furniture, vehicles, houses?

What happens when the digital revolution that has happened in music, movies, and now books comes to the rest of our possessions?

When we have digital designs for all our favourite possessions, will we just instantiate possessions when we need them and recycle them when we’re finished?

What about ‘physical piracy’ and ‘physical DRM’?

If we can duplicate food, what about the ethics of trying to duplicate living animals and humans? What if the only available 3d scanning techniques are destructive i.e. to duplicate a living organism you have to kill it in the process?

Another way of looking at things is in the wider context of creating low-cost alternatives for the tools needed for a small community to be self-sustaining. In [9] the Open Source Ecology project is introduced that is trying to do just that. At the moment a low-cost 3D printer is only one of 50 tools they are creating. Maybe in a decade this number will drop significantly due to more sophisticated 3D printers. How could projects such as this change the developing world? Or even the developed world?

Video links

[1] Scott Summit – The Future of 3D printing, June 28 2010, 50 minutes http://www.youtube.com/watch?v=6lJ8vId4HF8

[2] Nueve Ojos Full Printed – Manufacturing past present future 4 minute animation June 2010 http://vimeo.com/12768578

[3] TVNZ One News April 9, 2011 2 minute segment on 3D printing “Humble printer moves to 3D” http://tvnz.co.nz/technology-news/humble-printer-moves-3d-4109540/video?vid=4109534

[4] Desktop Nanofactory vision from 2006 : Productive Nanosystems – From molecules to superproducts 5 minute animation http://www.youtube.com/watch?v=zqyZ9bFl_qg

[5] Jay Lenos Garage 3D printer and scanner (not included in talk as I don’t have local copy of video) June 29, 2011 8 minutes http://www.jaylenosgarage.com/extras/articles/jay-lenos-3d-printer-replaces-rusty-old-parts-1/

[6] Star Trek – Picard “Tea, Earl Grey, Hot” montage video (27 seconds) http://www.youtube.com/watch?v=R2IJdfxWtPM

TED Talks

[7] TED 2011 – Lisa Harouni – A Primer on 3D printing 15 minutes http://www.ted.com/talks/lang/en/lisa_harouni_a_primer_on_3d_printing.html

[8] TED 2011 – Anthony Atala – Printing a Human Kidney 17 minutes http://www.ted.com/talks/lang/en/anthony_atala_printing_a_human_kidney.html

[9] TED 2011 – Marcin Jakubowski – Open-Sourced blueprints for civilization 4 minutes http://www.ted.com/talks/lang/en/marcin_jakubowski.html

[10] TEDxVienna 2011 – Klaus Stadlmann – The world’s smallest 3D Printer http://www.youtube.com/watch?v=D2IQkKE7h9I

Reprap specific videos

[11] Reprap General Introduction, linked from Reprap wiki frontpage http://reprap.org 8 minutes http://vimeo.com/5202148

[12] Dr Adrian Bowyer’s 2010 FOSDEM Reprap talk 51 minutes http://video.fosdem.org/2010/maintracks/reprap.xvid.avi

[13] Vik Olliver’s 2006 AuckLUG Reprap talk 61 minutes http://archive.org/details/AucklandLUG_RepRapProject_video

Other links

[14] Worlds smallest 3D printer http://3dmicroprinter.com/

[15] Erik de Bruijn MSc Thesis “On the Viability of the Open Source Development Model for the Design of Physical Objects – Lessons learned from the RepRap project” http://thesis.erikdebruijn.nl/master/MScThesis-ErikDeBruijn-2010.pdf

[16] Gada Prize http://humanityplus.org/projects/gadaprize/

[17]CRN Scenario Positive Expectations (starting with hobbyist 3D printing taking off) http://www.crnano.org/CTF-Scenario2.htm, one of a group of 8 scenarios produced during a 2007 workshop. See www.crnano.org/CTF-Scenarios.htm